Professional Passivation, Cleaning & High-Velocity Flushing

CXP Solutions delivers certified stainless steel passivation, high-velocity flushing, and industrial cleaning for pharmaceutical, EV battery, data center, aerospace, and semiconductor facilities nationwide. Zero accidents in 10+ years. Owner-led execution on every project.

Explore Our Capabilities

Click a service below to learn more about how we deliver excellence.

Stainless Steel Passivation

Professional citric and nitric acid passivation for piping, tanks, and vessels. We restore corrosion resistance and create audit-ready documentation following ASTM A967 and A380 standards.

High-Velocity Flushing

Turbulent flow flushing at 5-10 ft/sec removes weld slag, debris, and contaminants from new piping systems. Essential for construction commissioning and system startup.

Industrial Cleaning & CIP

Comprehensive cleaning services including clean-in-place systems, alkaline degreasing, and chemical cleaning. We match the right chemistry to your application.

Derouging Services

Professional rouge removal and re-passivation. Rouge (iron oxide contamination) forms from inadequate passivation or aggressive CIP chemicals. We restore surfaces to a properly passivated state.

Hydrostatic Testing

Pressure testing services for piping systems, vessels, and equipment. We verify system integrity with chart-recorded results and complete documentation packages for commissioning and compliance.

Pharmaceutical Passivation

GMP-compliant passivation for WFI systems, bioreactors, and clean steam. We understand FDA audits and deliver IQ/OQ documentation packages that keep your facility audit-ready.

EV Battery & NMP Systems

Specialized expertise in NMP solvent systems, electrode coating lines, and battery cell production equipment. We've worked with Toyota Battery Manufacturing, helping build the future of electric vehicles.

Data Center & AI Cooling

AI and HPC facilities need clean cooling loops. We protect microchannels, cold plates, and rear-door heat exchangers with proper flushing protocols designed for sensitive cooling infrastructure.

The CXP Passivation Process

Click each step to learn more about our proven methodology.

Step 1: Inspection & Assessment

Before any work begins, we thoroughly survey all welds, surfaces, and system components. This initial assessment identifies contamination levels, surface conditions, and any special considerations for your system.

- Visual inspection of all welds

- Surface condition assessment

- Contamination identification

- Custom protocol development

Step 2: Alkaline Degreasing

Oils, greases, and organic contaminants are removed using alkaline cleaning solutions. This critical step ensures the passivation chemistry can properly contact the stainless steel surface.

- Removes oils and greases

- Temperature controlled

- Prepares surface for acid

- Thorough rinse follows

Step 3: High-Velocity Flushing

Water is circulated at 5-10 ft/sec to create turbulent flow that physically removes weld slag, debris, and loose particles. This mechanical cleaning is essential before chemical treatment.

- 5-10 ft/sec flow rates

- Turbulent flow regime

- Multi-stage filtration

- Flow data logging

Step 4: Acid Passivation

Citric or nitric acid solution is circulated to remove free iron and enhance the chromium oxide passive layer. Temperature, concentration, and contact time are precisely controlled per ASTM standards.

- Citric or nitric acid

- ASTM A967 methods

- Time/temp controlled

- Concentration logged

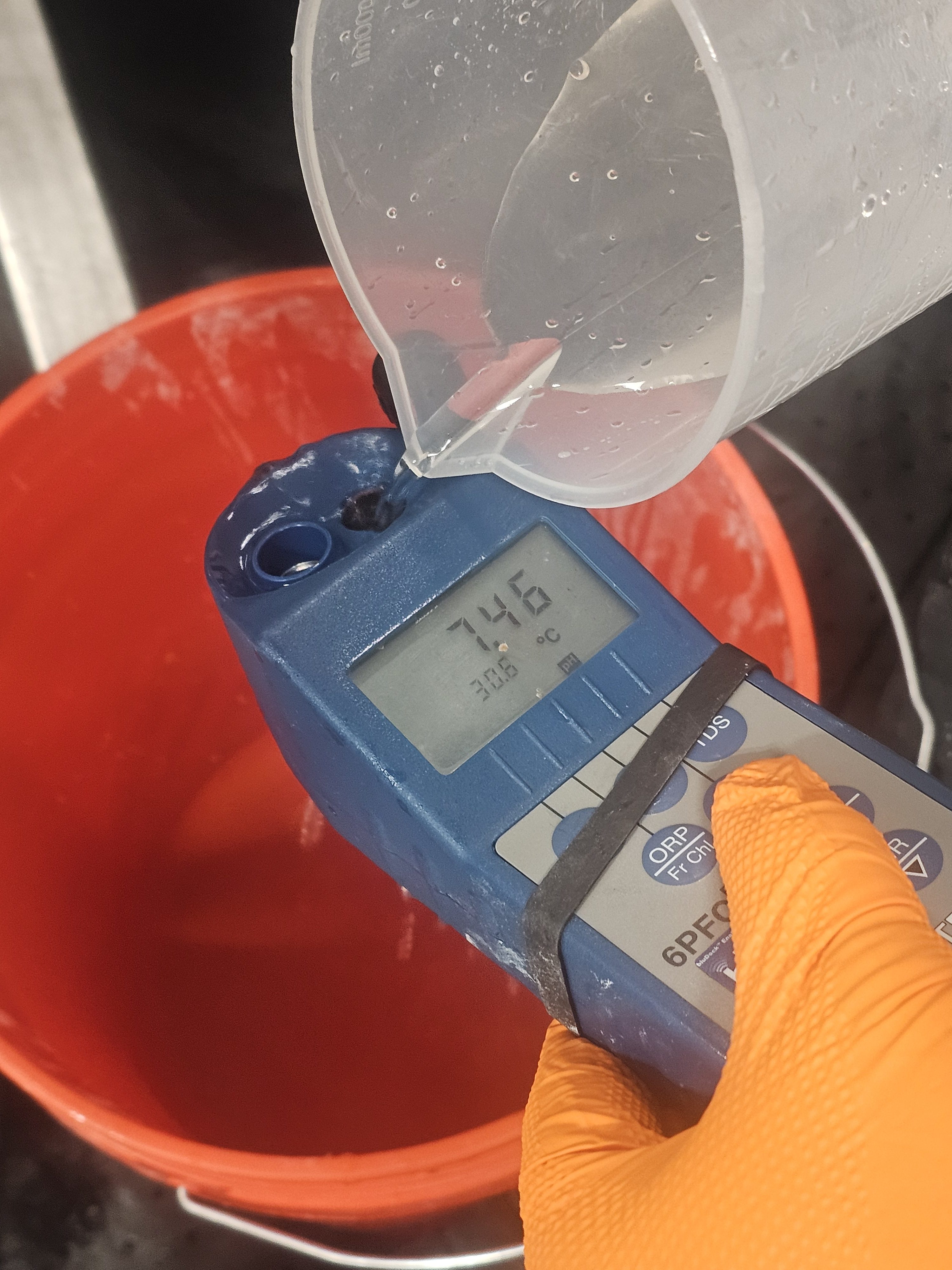

Step 5: Neutralization & Rinse

After passivation, the system is thoroughly rinsed and neutralized to remove all acid residue. pH is monitored to confirm complete neutralization before proceeding to verification.

- Complete acid removal

- pH verification

- Multi-stage rinse

- Conductivity testing

Step 6: Verification & Documentation

Passivation effectiveness is verified using copper sulfate or ferroxyl testing. Complete documentation packages include batch records, test results, before/after photos, and chemical certifications.

- Copper sulfate testing

- Ferroxyl testing available

- Complete batch records

- IQ/OQ packages

Derouging & Passivation Transformations

Drag the slider to see the dramatic difference professional derouging and passivation makes.

Before

After

Before

After

Pharmaceutical Fitting Restoration

Heavy Class II rouge contamination removed and surface re-passivated per ASTM A967. Copper sulfate verification confirmed successful treatment. Zero QA comments at audit.

Learn About Derouging →

Before

After

Before

After

Storage Tank Derouging

Complete rouge removal and ASTM A967 passivation for a pharmaceutical storage tank. Restored corrosion resistance and delivered full documentation package within maintenance window.

Rouge Classification Guide →

Built for Teams That Can't Afford Surprises

From pharmaceutical cleanrooms to EV battery plants — we've delivered flawless passivation across every demanding industry. Zero accidents. 100% audit-ready documentation.

About CXP →Passivation & Cleaning for Every Industry

From pharmaceutical cleanrooms to aerospace manufacturing — we bring the same precision to every project.

Why Leading Facilities Choose CXP Solutions

Built on integrity, technical expertise, and zero-compromise execution.

Owner on Every Project

Direct accountability and rapid decision-making. No subcontractors, no middlemen — experienced professionals who own results.

Zero Accidents in 10+ Years

Perfect safety record across pharmaceutical, aerospace, EV battery, and industrial facilities. Safety engineered into every procedure.

ASTM A967/A380 Compliant

Every passivation follows industry standards. GMP, FDA, and audit-ready documentation delivered as standard.

Rapid Mobilization

Mobile equipment ready for emergency response or scheduled commissioning support nationwide.

Cross-Industry Expertise

From aerospace to pharma, EV battery to data centers — passivation mastery across every demanding industry.

Transparent Pricing

No hidden fees. Clear quotes, honest timelines, complete transparency from estimate through completion.

Passivation & Cleaning Results

Actual results from completed projects.

Passivation & Cleaning Questions

Common questions about our services.

Ready to Get Started?

Get in touch for passivation, flushing, or cleaning services. Same-day response guaranteed. 24/7 emergency service available.